Collection: All Products

-

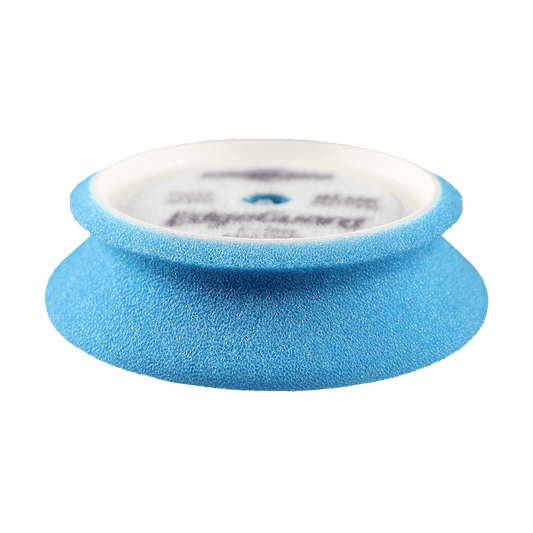

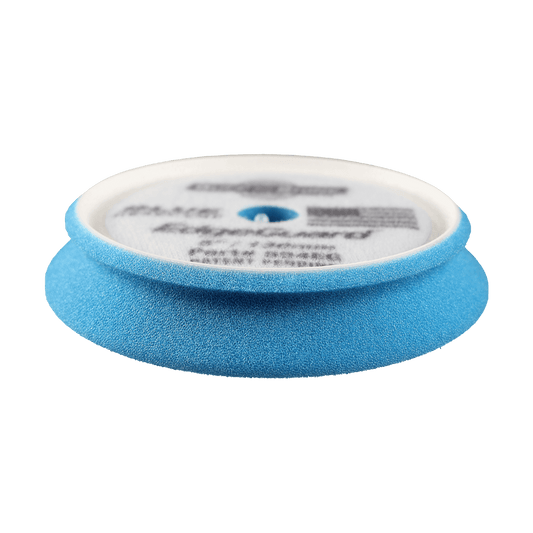

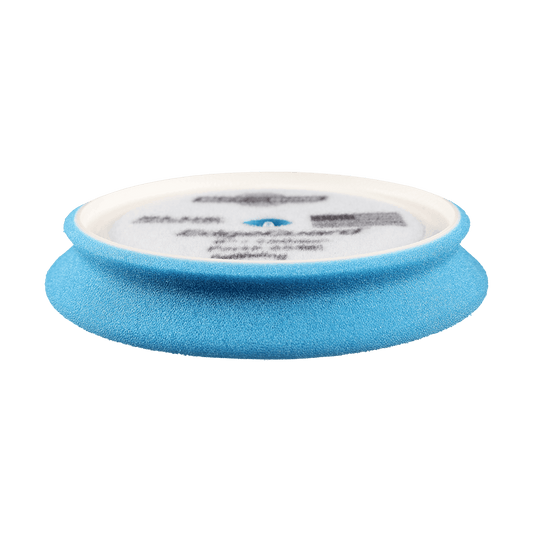

354EG - 3" Blue Coarse EdgeGuard™ Foam Pad - Heavy Cut

Regular price $0.00 USDRegular price -

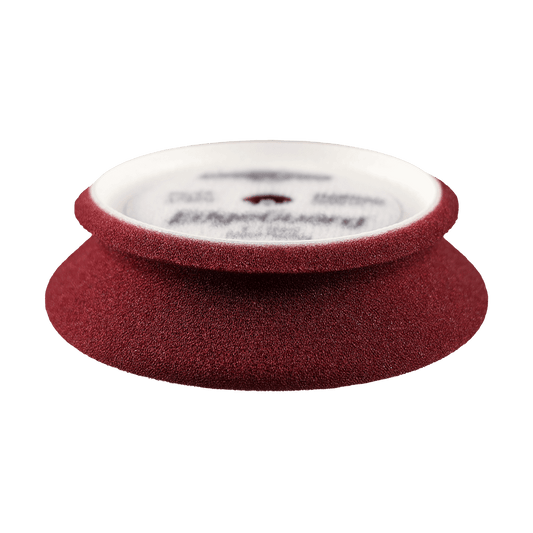

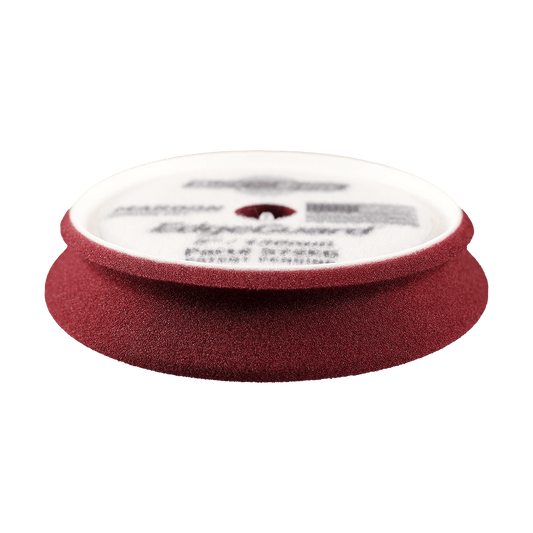

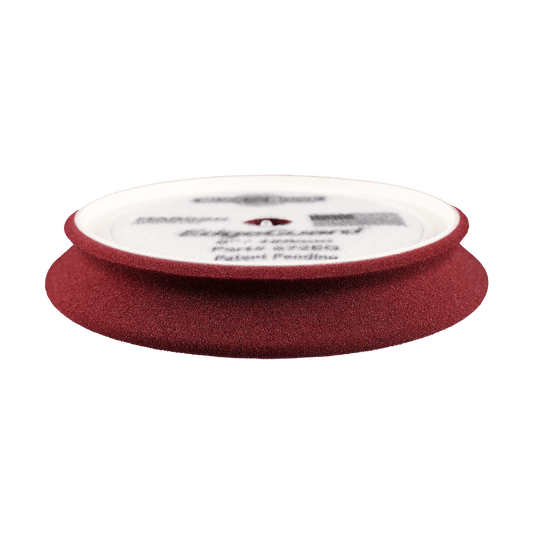

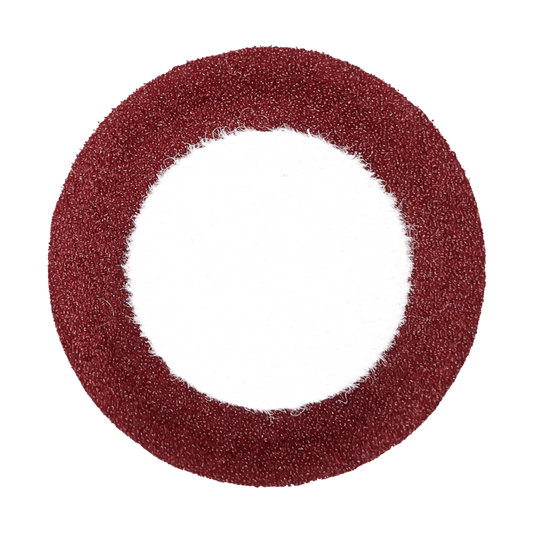

372EG - 3" Maroon EdgeGuard™ Foam Pad - Medium Cut

Regular price $0.00 USDRegular price -

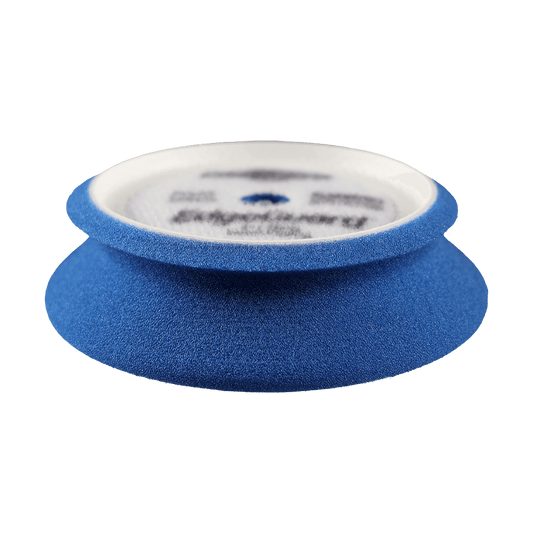

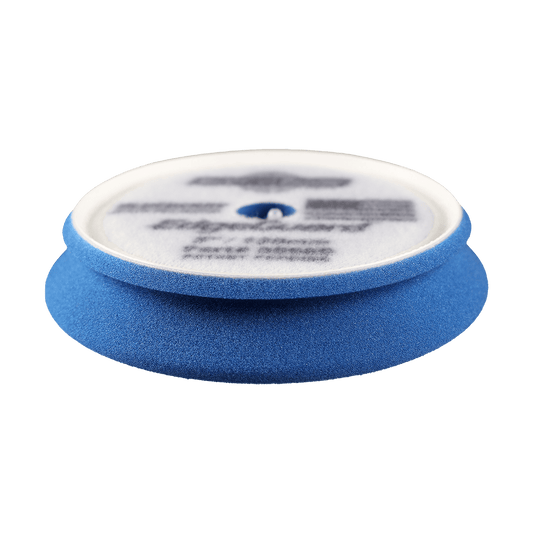

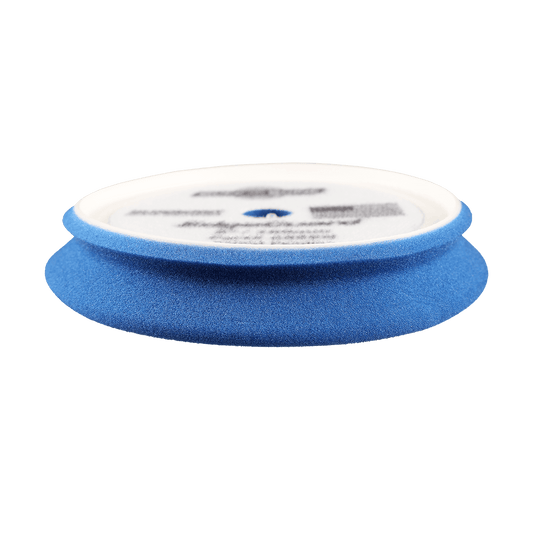

356EG - 3" Blueberry EdgeGuard™ Foam Pad - Heavy Polishing

Regular price $0.00 USDRegular price -

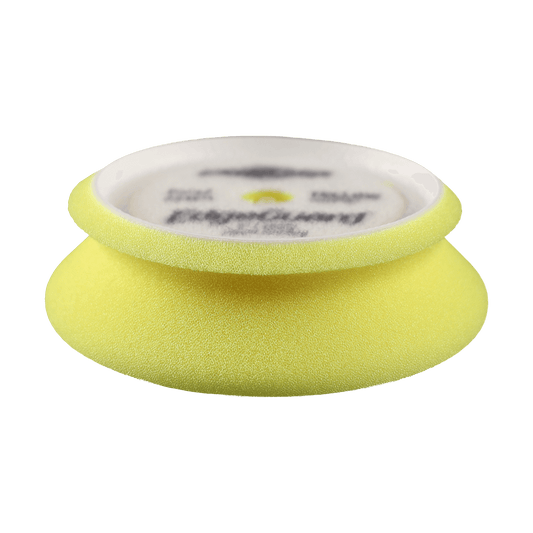

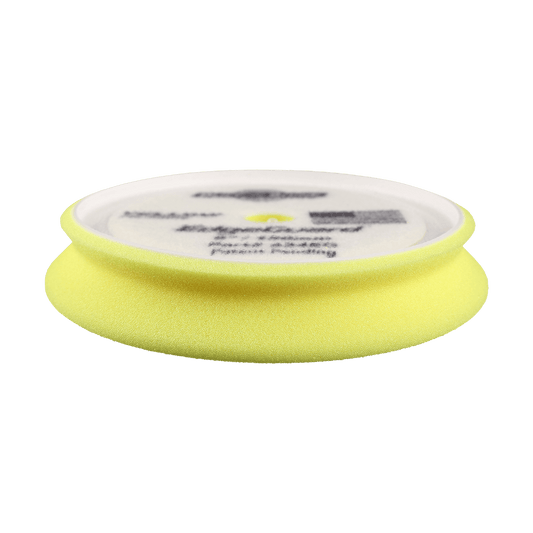

334EG - 3" Yellow EdgeGuard™ Foam Pad - Polishing

Regular price $0.00 USDRegular price -

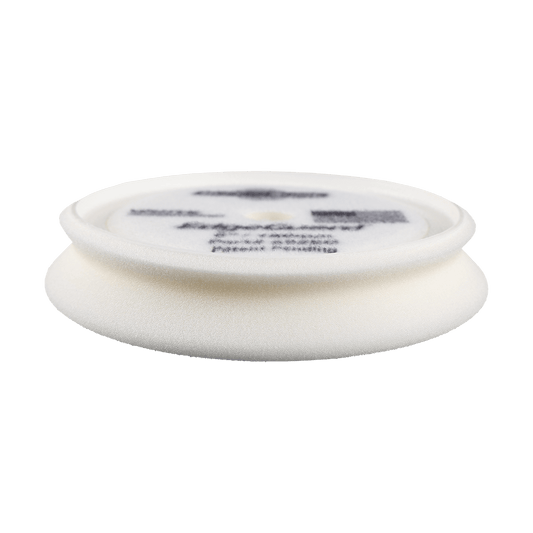

392EG - 3" White EdgeGuard™ Foam Pad - Polishing/Finishing

Regular price $0.00 USDRegular price -

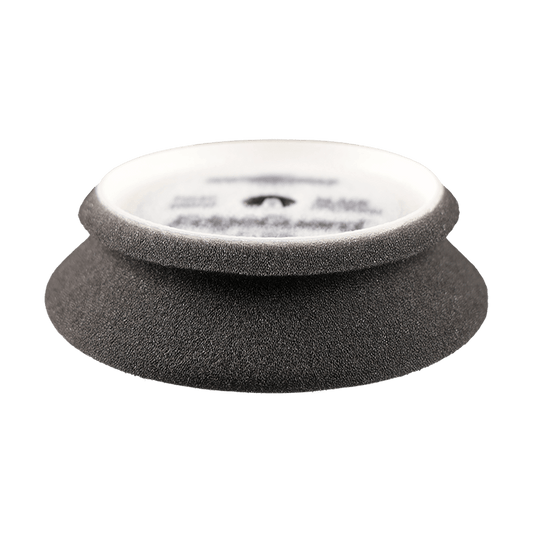

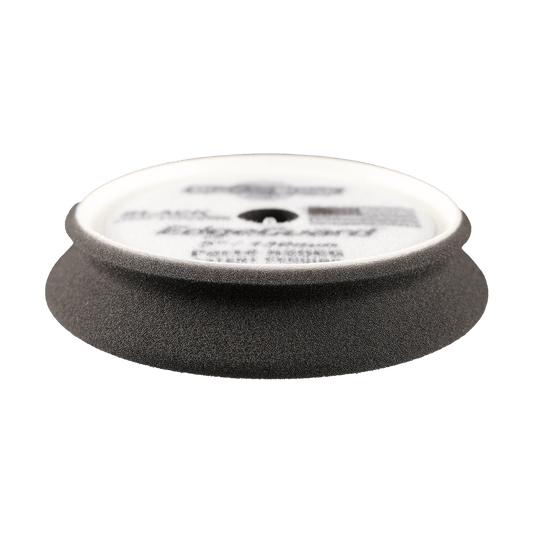

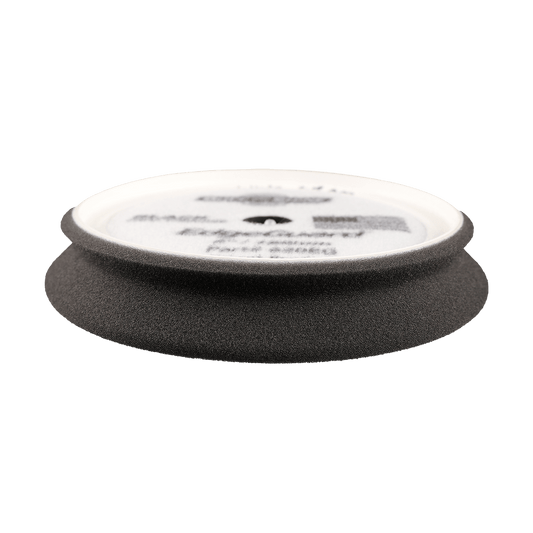

320EG - 3" Black EdgeGuard™ Foam Pad - Final Finishing

Regular price $0.00 USDRegular price -

554EG - 5" Blue Coarse EdgeGuard™ Foam Pad - Heavy Cut

Regular price $0.00 USDRegular price -

572EG - 5" Maroon EdgeGuard™ Foam Pad - Medium Cut

Regular price $0.00 USDRegular price -

556EG - 5" Blueberry EdgeGuard™ Foam Pad - Heavy Polishing

Regular price $0.00 USDRegular price -

534EG - 5" Yellow EdgeGuard™ Foam Pad - Polishing

Regular price $0.00 USDRegular price -

592EG - 5" White EdgeGuard™ Foam Pad - Polishing/Finishing

Regular price $0.00 USDRegular price -

520EG - 5" Black EdgeGuard™ Foam Pad - Final Finishing

Regular price $0.00 USDRegular price -

654EG - 6" Blue Coarse EdgeGuard™ Foam Pad - Heavy Cut

Regular price $0.00 USDRegular price -

672EG - 6" Maroon EdgeGuard™ Foam Pad - Medium Cut

Regular price $0.00 USDRegular price -

656EG - 6" Blueberry EdgeGuard™ Foam Pad - Heavy Polishing

Regular price $0.00 USDRegular price -

634EG - 6" Yellow EdgeGuard™ Foam Pad - Polishing

Regular price $0.00 USDRegular price -

692EG - 6" White EdgeGuard™ Foam Pad - Polishing/Finishing

Regular price $0.00 USDRegular price -

620EG - 6" Black EdgeGuard™ Foam Pad - Final Finishing

Regular price $0.00 USDRegular price -

154CR - 1" Blue Coarse URO TEC® Foam Pad - Heavy Cut

Regular price $0.00 USDRegular price -

172CR - 1" Maroon URO TEC® Foam Pad - Medium Cut

Regular price $0.00 USDRegular price